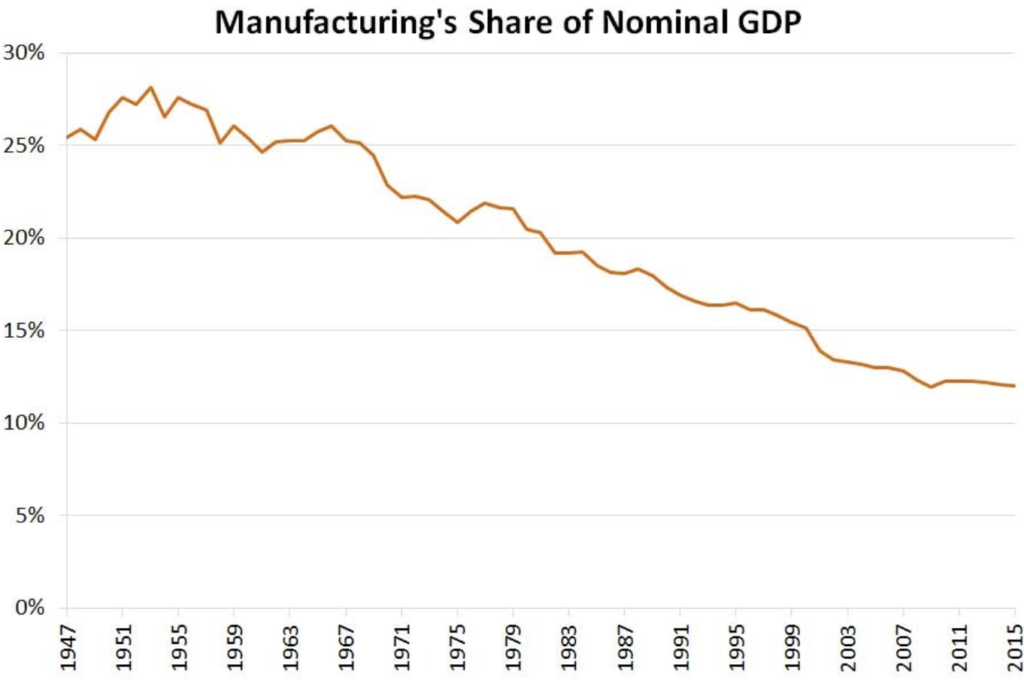

Software represents the futuristic path, an avenue leading us rapidly towards the merge. Meanwhile manufacturing feels like a dying space, at least in the United States. And the data reflect that.

But just because manufacturing’s share of GDP has been decreasing does not mean it must continue that way. Even at an all-time low of ~11% of the U.S GDP, manufacturing still makes up a $4.7 trillion industry in the U.S., employing over 12.9 million Americans.

In the silicon valley bubble, young workers seem to look at the prospect of working in manufacturing with the same level of excitement as starting an artisan candle store.

As a senior at Berkeley, I personally have not met a single Cal student who stated their ambitions to enter and create value for this industry. The paradigmatic shift towards software, while justified, has likely led us to turn a blind eye towards the importance of creating and distributing physical goods. As a reminder, ’twas merely 6 months ago when mass panic buying left shelves empty and supply chains crippled due to overwhelming demand in manufacturing and distribution.

There exists a deep and fundamental reliance on physical products in nearly every aspect of our lives. To illustrate this, simply look around your room and search for an item you use daily that has not been mass-manufactured.

An interesting opportunity may be ahead. Consider 2 things:

(1) There exists tunnel vision in the startup community towards software as the future of everything.

(2) There exists a huge and unfaltering reliance on manufactured physical goods for quality of life across the U.S. & the globe.

So let us explore the burning question: Is manufacturing being overlooked by the startup community? What problems need to be addressed to increase efficiency in production? How might advances in software & machine learning facilitate a resurgence in the innovation & domestic production of goods?

Fortunately, you don’t have to listen to my opinions. We at the SCET sourced a qualified group of panelists to answer these questions and more. Throughout an hour-long Innovation-X Roundtable, moderator Ryan Kelly sampled perspectives from a variety of industry experts on the state of manufacturing and industry.

Below are the most important questions & takeaways from this discussion:

Participants: Ryan Kelly (GM of Association for Manufacturing Technologies SF Tech Lab), Cathy Ma (Head of Audience Development @ Thomas), J.D. Sassaman (Sr. Manager, Manufacturing Engagement @ Autodesk), Saifu Muhammad (Group PM & Design Manager @ Xometry), Megan Brewster (VP of Advanced Technology @ Impinj).

What is the future of manufacturing in your respective field?

- Accessible, user-friendly products and services that small and medium sized business can use to do work in connected, distributed, and integrated ways. (“You’d think this sounds not-so-ambitious, but in reality it is so different from what it is today.”)

- Supply chains that are ultra efficient, where you can track the visibility and status of every single item.

- Innovate & design better physical products which directly make the world a better place.

- Align educational institutions, companies, startups to do rapid prototyping and testing for designs and construction.

What are some problems that our audience (and the public in general) should be excited about?

- The democratization of knowledge. A wikipedia model for manufacturing. We need to connect manufacturers to data and to people.

- There is a missed opportunity to get people easily certified, bring them in, and get them excited about the industry. It is easy to learn UX design or web programming online — everything is out there, and available. This is not the case for manufacturing.

- There is too much embodied wisdom on the factory floor. We need a connection between the physical layer of machinery and the digital layer of information.

- Building better design tools for manufacturing and construction.

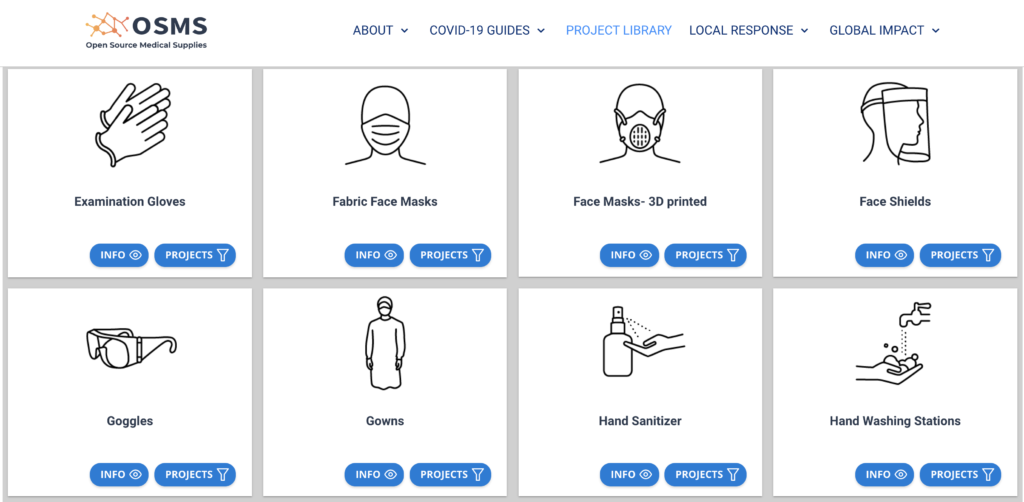

What is an example of information democratization in manufacturing?

- When Covid hit, demand for PPE soared overnight. Supply chains couldn’t keep up.

- What Open Source Medical Supplies (OSMS) is doing is collecting open source blueprints for common medical supplies and publishing those for free to support local manufacturing.

- In this case, the competitor is not another business; the competitor is the virus.

- This model for democratized, open-source manufacturing information has massive potential.

Why aren’t students excited by manufacturing?

- It’s one of those industries that, when you’re in college and thinking about your career, you don’t hear about it. You don’t even consider it.

- Everyone who graduates CS wants to go to Google, Facebook, or Amazon. So the talent pooled gets shoved into those industries. Meanwhile manufacturing, which could benefit massively from this talent pool, is left unchanged. That’s the uphill battle we are facing.

How do we make them excited?

- Physical solutions are a change in how we live. The problems are real and tangible.

- There is a kind of empowering experience you have when you make something in real materials that ends up in the world, at scale.

- If the image and experience of that feeling of empowerment can be shown to folks who are interested in CS & developing digital tools and data analytics, we can construct the future of manufacturing in an entirely different way.

What do you see as the most important development for manufacturing?

- There is a huge problem with manufacturing that the startup community has already solved for elsewhere

- It is the problem of data standardization & blueprint standardization

- If we have a shared schematic understanding of materials and objects, we can share and transfer knowledge much faster

- Take Facebook’s open-graph technology, or Google’s search schema. If you’re in SEO optimization, and your website has no labeled metadata, you won’t be seen by Google. This encourages web developers adhere to a standard of metadata labeling.

- What is the equivalent for our sector? If we can solve for this problem, innovation in our sector will grow exponentially.

What should Berkeley students be doing, collaborating on, or working on in this space?

- What needs to happen now is a swing for the fences.

- We need to encourage the private sector to invest in manufacturing tech startups.

- We need more strongly unified certifications which show supply chain transparencies.

- We need AI, IoT, data analytics, object tracking. We need to set these technologies loose in our sector.

- There is so much space in manufacturing for innovation. Students should focus on specific, unique points of friction. Go out and talk to people in this space.

End of Panel.

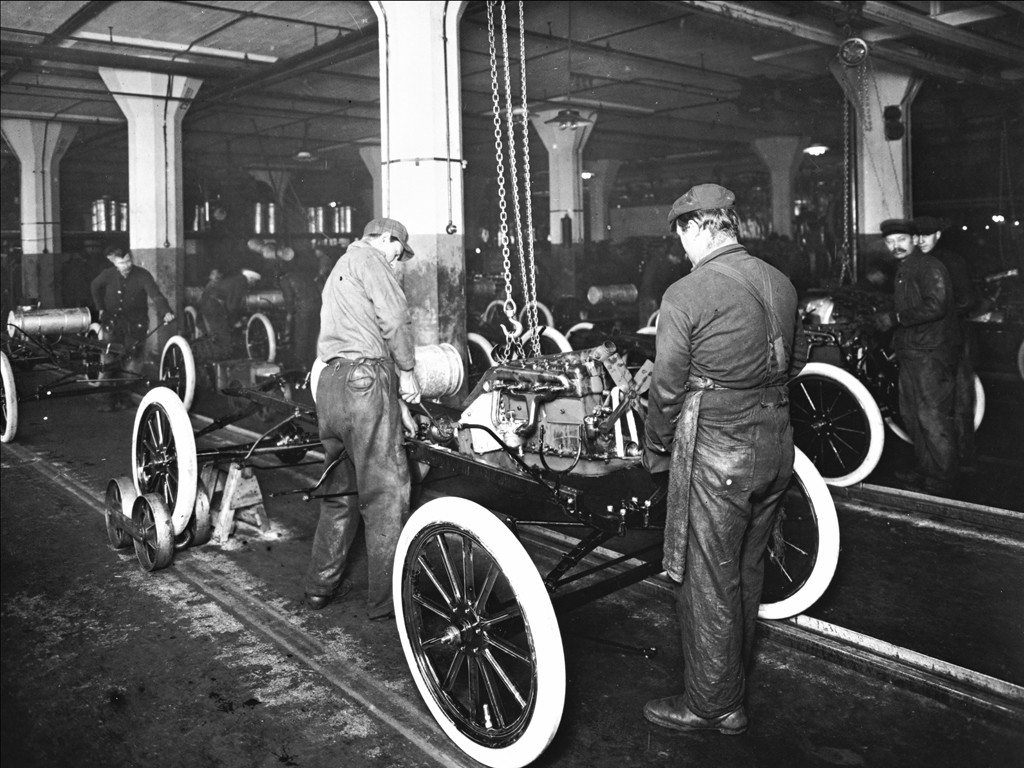

Hopefully the insights from these panelists spark ideas from student entrepreneurs eager to solve problems that are being overlooked in the manufacturing industry. Finally, to leave off on a foot of inspiration, below you can see what 100 years of manufacturing innovation looks like.